|

| COMPONENTS OF ATLANTIC SYSTEM (FLOATING PONTOONS) |

| |

|

|

| |

|

| Structure |

| |

Made from A 42 b steel sections that have been protected against corrosion through hot galvanisation by immersion, in compliance with UNE EN ISO 1461:1999.

Lateral ‘C’-shaped sections allow finger berths to be added, and these can be placed anywhere along the length of the pontoon. Docking hoops can also be attached.

Moment of inertia Ix: 661.9cm4

Unit of resistance Wx: 82cm3

Lattice made from square tube 60 x 60 x 4mm

Moment of inertia I: 42.30cm4

Unit of resistance W: 14.10cm3 |

| |

| |

|

| Deck |

| |

Made from tropical Massaranduba (Manilkara Elata) wood.

Boards are 22mm thick and 140mm wide.

Density: 1,200kg/m3.

Hardness (Monnin scale): 14.6 % (very hard).

Highly resistant to fungi, termites, and other wood-eating and boring insects.

Unimpregnable, hard wood.

Grooved, non-slip finish.

Fixings are counter-sunk into the wood.

Stainless steel fixings. |

| |

|

| |

| |

|

| Unit dimensions |

| |

Modular systems facilitate transportation and assembly of the installations.

The Atlantic range comprises platforms of different lengths and/or widths:

AC0 … Length 10m … Width 3m

AC1 … Length 10m … Width 2.5m

AC2 … Length 12m … Width 2m

|

| |

| |

|

| Side fenders |

| |

Tropical ‘Massaranduba’ wood fender measuring 160 x 45mm. This is highly resistant and is firmly fastened to the top of the structure’s ‘C’-shaped sections. Tropical ‘Massaranduba’ wood fender measuring 160 x 45mm. This is highly resistant and is firmly fastened to the top of the structure’s ‘C’-shaped sections.

|

| |

| |

|

| Utility ducts |

| |

Duct section 90 x 175mm. Duct section 90 x 175mm.

Easy to use.

Covered with anodised aluminium panels.

Grooved, non-slip finish.

|

| |

| |

|

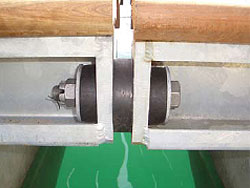

| Elastomer joints between pontoons |

| |

The structure uses rubber rings and galvanised steel washers that work together in order to allow a certain degree of movement between pontoon sections. The structure uses rubber rings and galvanised steel washers that work together in order to allow a certain degree of movement between pontoon sections.

The elastomers are made from artificial and synthetic rubber in the shape of perbuna and are very resistant to saline solutions, acids, bases, aliphatic hydrocarbons, mineral oils, benzene and alcohol. They are durable and have high mechanical resistance. |

| |

| |

|

| Concrete floats |

| |

Coated with AISI 316 stainless steel bar reinforced concrete and an LDVB grade expanded polystyrene core.

Core density: 11kg/m3

Weight of concrete: 40N/mm2

No. of floats per pontoon section: 2.

Sections that support access gangways contain an additional float.

Joined to the structure of the pontoon with 4 stainless steel bolts that are embedded into the corners of the float and welded to the reinforcing frame.

All the joints are fitted with rubber rings to absorb any movements and vibrations, minimising the transmission of any stress from the pontoon to the floats.

|

| |

Ref. |

Length |

Width |

Height |

Weight |

DF0 |

2.870 mm |

2.370 mm |

810 mm |

1.850 kg |

DF1 |

2.370 mm |

1.870 mm |

735 mm |

1.125 kg |

DF2 |

2.870 mm |

1.500 mm |

750 mm |

1.155 kg |

|

| |

| |

|

| Polyethylene floats |

| |

Polyethylene cover with polystyrene core. Polyethylene cover with polystyrene core.

Dimensions: Up to 12 different sizes with different pressures and buoyancy.

No. of floats: Varies according to use and

size of the pontoon.

Set out like a catamaran under the pontoon.

Fixed to the pontoon structure by four stainless steel bolts.

|

| |

|

| |

Ref. |

Length |

Width |

Height |

Net volume |

RF517 |

1.100 mm |

500 mm |

700 mm |

347 L |

RF506 |

1.500 mm |

500 mm |

600 mm |

405 L |

RF507 |

1.500 mm |

500 mm |

700 mm |

473 L |

RF508 |

1.500 mm |

500 mm |

800 mm |

540 L |

RF554 |

1.950 mm |

550 mm |

450 mm |

434 L |

RF555 |

1.950 mm |

550 mm |

525 mm |

507 L |

RF706 |

1.500 mm |

700 mm |

600 mm |

567 L |

RF707 |

1.500 mm |

700 mm |

700 mm |

662 L |

RF708 |

1.500 mm |

700 mm |

800 mm |

756 L |

RF906 |

1.500 mm |

900 mm |

600 mm |

729 L |

RF907 |

1.500 mm |

900 mm |

700 mm |

851 L |

RF908 |

1.500 mm |

900 mm |

800 mm |

972 L |

|

| |

| |

| |

| |

|