|

| EQUIPMENT FOR PONTOONS, PIERS AND LAUNCH RAMPS |

| |

|

|

| |

| Direct anchorage from the pontoon to the pier and to the seabed |

| |

|

| Pontoon-pier guiding girders with clamps |

| |

Guided system for a set of HB 160 girders that are vertically attached to the pier with chemical anchors and a clamp with two nylatron rollers that are firmly fixed to the pontoon. Guided system for a set of HB 160 girders that are vertically attached to the pier with chemical anchors and a clamp with two nylatron rollers that are firmly fixed to the pontoon.

The rollers allow the pontoon to move vertically as it follows the movement of the waves and the tide, but horizontal movement of the pontoon is avoided as it is firmly fixed to the pier.

Weights: 1,750, 2,750 and 5,000kg. |

| |

|

|

|

| |

|

| Jointed pontoon-pier connecting rods and platforms |

| |

Normally used on pontoons that are attached to stone walls or on a seabed with a slight incline where some distance should be maintained between the pontoon and the point of anchorage.

Like the previous system, this one allows the pontoon to move vertically but stops it moving horizontally by using jointed connecting rods at each end and/or jointed access platforms. |

| |

|

| |

| |

|

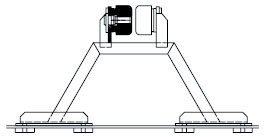

| Pile system connecting the pontoon to the seabed |

| |

This system comprises piles that are driven into the seabed and joined to the pontoon by side clamps and interior clamps that allow the pontoon to move with the waves and tides but prevent it from moving horizontally.

These posts are made from ST 52 steel, and their diameter, wall thickness and length vary according to the depth and characteristics of the seabed. These dimensions are calculated be geo-technical studies of the terrain.

The entire surface of the posts is treated against corrosion with SA-25 blasting, 70/75 micron zinc silicate primer and a 150 micron coat of epoxy enamel.

The clamps that hold the pontoon can be placed on the side of the pontoon or inside it, according to the client’s requirements and the characteristics of the installation. There are highly resistant elastomer pads on the inner edge to cushion any potential jerks and friction. The clamps that hold the pontoon can be placed on the side of the pontoon or inside it, according to the client’s requirements and the characteristics of the installation. There are highly resistant elastomer pads on the inner edge to cushion any potential jerks and friction.

|

| |

| |

|

| |

| |

| |

|