|

| GANGWAY COMPONENTS (Page 2 of 2) |

| |

|

| |

|

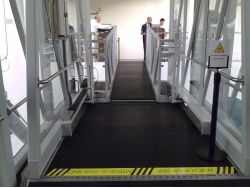

| Coverings and Finishes |

| |

The gangways’ internal coverings and finishes can give them a pleasant, aesthetic appearance, as well as providing elegance and safety.

The great variety of materials, options and designs makes it possible to create different projects that are personalised according to specific requirements.

- Tubular side rails.

- Different thickness polycarbonate and methracrylate panels cover the tunnel.

- Multi-layer panels with mineral element insulation.

- Stadip or Climalit glass side walls with an air chamber and double glazing.

- Stainless steel safety handrail, AISI 316L marine quality.

- Interior illumination.

- Ventilation and air conditioning systems for internal areas. |

| |

|

| |

| |

|

| Access |

| |

In order to carry out maintenance work, there is a safety cage along the gantry’s main girder and around a ladder attached to its leg, and inspections can be carried out from the quay or from the fixed gangway. In order to carry out maintenance work, there is a safety cage along the gantry’s main girder and around a ladder attached to its leg, and inspections can be carried out from the quay or from the fixed gangway.

|

| |

| |

|

| Independent flotation tracking system |

| |

ITP’s independent flotation system allows the boarding gangway to follow the vessel’s small movements and the natural listing in port that are caused by waves and the tide.

This system is complemented by the safety systems and alarms that keep the gangway within its operational service margins. |

| |

|

| |

| |

|

| Safety mechanisms |

| |

- Cut-off switches when in motion. - Cut-off switches when in motion.

- Light and sound warnings when in motion.

- Light and sound warnings when reaching cut-off points.

- Anti-storm system.

- Cut-off switches for maximum and minimum horizontal and vertical inclination.

- The gangway is rabetted, which provides a blocking system to stop it falling vertically if the boat’s support is lost.

- Residual current devices and current breakers in the electric box.

- Emergency stop button in the operator locations and on the legs at the quay level.

- Handrail and ladders with safety cages on all means of access.

- Bumpers and pedestrian warning sensors.

- Mechanical safety catches. |

| |

|

| |

|

| |

| |

|

| Power supply |

| |

Power comes through an automatic reel that can store the electric lead, which is connected to the three-phase supply available in the port. Power comes through an automatic reel that can store the electric lead, which is connected to the three-phase supply available in the port.

|

| |

| |

|

| Control panel |

| |

Connection and disconnection of the telescopic gangway to and from the boat is directly controlled through touch-screen controls with a radio-control push-button panel to facilitate connection operations between the gangway and the boat. The operator can be on the jointed/telescopic section or even on the quayside during these manoeuvres. Connection and disconnection of the telescopic gangway to and from the boat is directly controlled through touch-screen controls with a radio-control push-button panel to facilitate connection operations between the gangway and the boat. The operator can be on the jointed/telescopic section or even on the quayside during these manoeuvres. |

| |

|

| |

| |

|

| Protective, anti-corrosion treatment |

| |

1. All surfaces are sandblasted with SA 2 ½ sand.

2. The entire structure is cleaned with compressed air.

3. A primer coat of zinc-rich epoxy is applied (HEMPADUR ZINC 15360, 60 micron coat).

4. The whole structure is pressure washed with soapy water and then allowed to dry.

5. A base coat of two-component epoxy paint is applied (HEMPADUR HI-BUILD 45200, 100 micron coat).

6. The entire structure is cleaned with compressed air.

7. Two coats of two-component aliphatic isocyanate, polyurethane gloss enamel are applied (HEMPEL’S POLYENAMEL 55100, 40 microns each coats).

|

| |

| |

|

|