|

| DOUBLE BOOM CRANES (Page 5 of 5) |

| |

|

| |

|

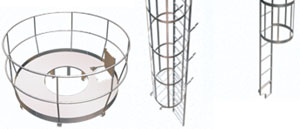

| Access |

| |

The double boom crane’s access features allow all the equipment and mechanisms to be checked and repaired.

|

|

These accesses comprise:

1. Vertical ladder with a safety cage fixed to the pivot allowing access to the turret.

2. Circular platform with a guardrail surrounding the turret that allows all the main electrical, hydraulic and mechanical equipment to be checked.

3. A set of ladders with safety cages and a small platform with a guardrail to allow inspection of the winch and the turret’s cylinder joint. |

| |

| |

|

| Surface protection and paint treatment |

| |

It is optional for the revolving structure (comprising the boom and turret) to be protected against corrosion through hot galvanisation by immersion, in compliance with UNE EN ISO 1461:1999. This treatment provides internal and external protection for the structure, thus delaying rusting and prolonging the crane’s working life.

The other structures are protected in the following way:

- Sandblasted with SA 2 ½ sand and cleaned with compressed air.

- Primed with a layer of 60 microns of Hempadur Zinc Primer 15360. Primed with a two-component, polyamide-cured epoxy paint with high zinc powder content. The whole surface is pressure washed with soapy water.

- Two 100 micron base coats of Hempadur Hi-Build 45200. A thick layer of two-component, polyamide-cured epoxy paint.

- Two 30 micron top coats of Hempel’s Polynamel 55100. Two-component aliphatic isocyanate, polyurethane gloss enamel. |

| |

| |

|

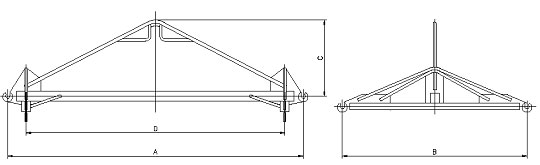

| Accessories |

| |

The crane is supplied with items for moving loads  that comprise a set of slings and a lifting frame with the appropriate dimensions for the intended vessels. that comprise a set of slings and a lifting frame with the appropriate dimensions for the intended vessels. |

The lifting frame’s special shape allows it to move sailboats with keels by placing the two heads parallel to the sides and the core perpendicular to the keel, which allows the mast to be freed.

Also, depending on the size of boat, the frame can be positioned with the core parallel to the keel. |

| |

MAXIMUM LOAD |

A |

B |

C |

D |

Weight |

4 Tm |

2.500 mm |

1.800 mm |

575 mm |

2.000 mm |

150 Kg |

6 Tm |

2.950 mm |

1.800 mm |

730 mm |

2.500 mm |

195 Kg |

8 Tm |

3.500 mm |

2.000 mm |

928 mm |

3.000 mm |

212 Kg |

10 Tm |

4.000 mm |

2.500 mm |

1.030 mm |

3.500 mm |

370 Kg |

|

|

|

| |

| |

| |

|

| |