|

| DOUBLE BOOM CRANES (Page 3 of 5) |

| |

|

| |

|

| Elevation mechanism |

| |

The main components of the elevation system are:

1. Hydraulic Winch 1. Hydraulic Winch

2. Pulley System

3. Lower Pulley System and Hook |

|

| |

| The elevation cable drives the lower pulley system from which the load is suspended, and goes through the pulleys at either end of the extension arm. The cable is guided through the oscillating structure, finishing at the pulleys at either end, to ensure that it doesn’t jump out of the pulleys, and the cables of the lower pulley system are also guided. |

| |

The lower pulley comprises two steel sheaves that turn on bearings and are attached to the revolving hook by two thick steel plates. In order to correctly position the cable, the lower pulley must be heavy enough to keep the cable taut. The lower pulley comprises two steel sheaves that turn on bearings and are attached to the revolving hook by two thick steel plates. In order to correctly position the cable, the lower pulley must be heavy enough to keep the cable taut.

There is a specially designed hydraulic winch, which is universally used in self-propelled cranes, to lift loads. It has a square structure so that it can be attached by any of the four sides. It contains the coil drum for multiple layers of cable and is driven by a planetary gearbox whose moving part is welded to the drum and whose fixed part is attached to the frame. The other end is supported on the framework with a bearing. |

| |

| |

|

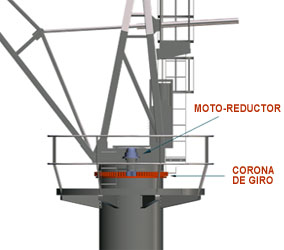

| Turning mechanism |

| |

A turning motion is achieved through a reduction drive group that is attached to the side of the turret and a sprocket that is attached to the top of a pivot. A turning motion is achieved through a reduction drive group that is attached to the side of the turret and a sprocket that is attached to the top of a pivot.

This mechanism allows a 360o range of motion that is worked by the control buttons.

As well as turning the crane’s superstructure, this mechanism helps counteract potentially unbalancing momentum through the disproportion between the load and its own weight.

There are two elements that help this aim: turning bearings and the gearbox. |

| |

| |

|

| Range mechanism |

| |

The articulated part of the retractable boom comprises the three previously mentioned structures (boom, brace and extension arm). It is moved by a hydraulic cylinder in order to vary the crane’s range.

Changing the range, like the other movements that characterise this sort of crane, is done with progressive manipulators and proportional electro-valves that allow the crane to make controlled movements at variable speeds. |

| |

| |

|

| |